We need hyperbaric testing to validate the design and manufacturing of products that are intended to work in subsea conditions, or other high pressure environments, giving manufacturers and their customers peace of mind that the product will perform correctly.

What are the benefits of hyperbaric testing?

Deploying equipment deep under water, or in other hazardous environments, is costly and often challenging. Therefore, it is vital to verify a product or component’s reliability under extreme pressure before it is deployed. This will increase efficiency and reduce the risk of unnecessary costs.

Hyperbaric testing is often used to test components that are then placed in to larger systems or pieces of equipment. Customers need to be sure that each component will perform as intended; if one small, but vital, component fails to function, it could result in costly and hazardous results.

Paul Smith, general manager of Tyne Subsea, explains: “It’s vital that manufacturing businesses meet their customers’ requirements and deliver products that work effectively, safely and provide the results which they have promised.

“Aside from this, the testing we perform also supports innovation for sectors where extreme conditions are the norm. As a team, it is especially rewarding when we work with customers to develop a testing programme that will contribute to the successful introduction of a new innovation, which will open up new opportunities. Recently we worked on a project testing electrical components to pressures that exceed that found at the deepest known ocean depth on Earth which will be used in a manned submarine to explore the Mariana Trench.”

The need for hyperbaric testing facilities

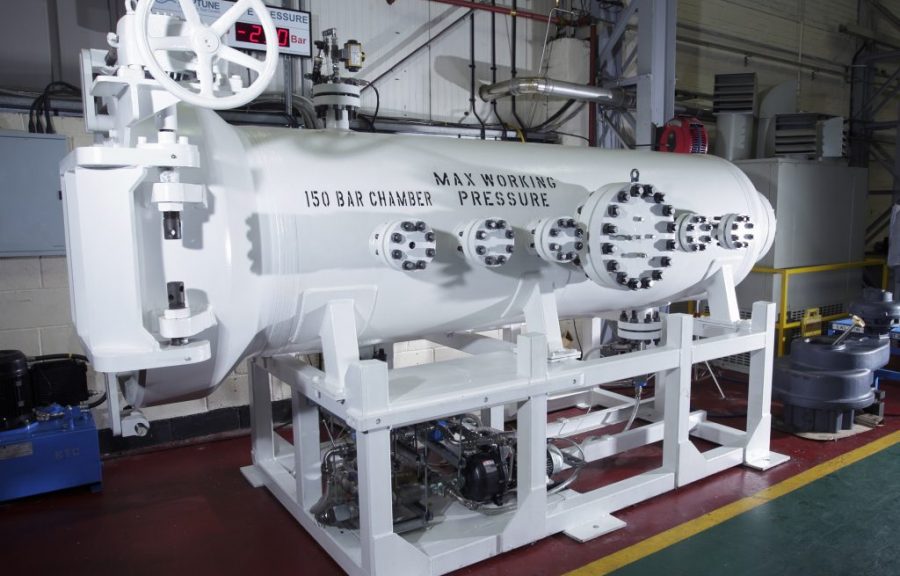

Tyne Subsea not only provides the standard hyperbaric services, but can also provide additional testing, certification and research services which further increase efficiency. We also offer multi-chamber testing capabilities, and the ability to provide 24/7 testing. Click here to find out more.

It is vital for facilities like Tyne Subsea to be able to provide dedicated facilities which operate the cutting-edge and specialist equipment that customers require to validate their products. It is also important that the services that these facilities provide are performed by technical experts, like Tyne Subsea’s technicians, who have over 20 years of experience in hyperbaric testing, who understand the industry and comprehend the customers’ needs.